What can we do?

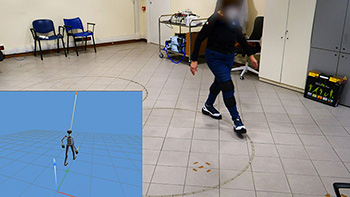

To achieve this goal, new wearable technologies, artificial intelligence, and humanoid robots can serve as true catalysts to transition from unstructured industrial ecosystems to future workplaces with minimal risk. Wearable technologies can monitor workers' physical conditions and provide real-time alerts, allowing proactive and preventive risk management thanks to the new processing techniques provided by artificial intelligence. Humanoid robots are intermediate, versatile, and easily adaptable solutions for unstructured industrial ecosystems to accelerate the necessary digital transformation, with the aim of assisting workers in high-risk activities. The combined use of these technologies has unprecedented potential in preventing musculoskeletal diseases in workers of the near future.

Why

According to the INAIL (Italian National Institute for Insurance against Accidents at Work) Annual Report on Occupational Diseases, in 2021, there were 55,205 reported cases of occupational diseases in Italy, with over 70% related to the musculoskeletal and connective tissue system. At the European level, according to the European Agency for Safety and Health at Work (EU-OSHA), musculoskeletal diseases are the main work-related health issue in Europe. Globally, musculoskeletal disorders related to work remain the most common occupational diseases. These data on musculoskeletal diseases highlight the need for a digital transformation of the Italian and international industries.

Acceptability and validation

The ergoCub project develops wearable technologies and humanoid robots while considering their acceptability, with the aim of reducing the number of musculoskeletal diseases related to biomechanical risk in future workers.

The adoption of new technologies represents an unprecedented opportunity to redefine the underlying theory and processes for biomechanical risk prevention. To achieve this redefinition process, the project validates the technologies in specific experimental fields, ultimately aiming to establish a spinoff that can transfer and distribute the technologies developed by the ergoCub project to the productive fabric and workplaces.

Ipsos

Acceptability survey

It is of fundamental importance that the design of new technologies takes into account their acceptability within the work context, considering their impact on workers' lives and society as a whole. Therefore, within the ergoCub project, a study is being conducted in collaboration with IPSOS to assess the reception and acceptability of wearable technologies and humanoid robots through a survey involving workers from the manufacturing and healthcare sectors. The study results can guide future technology development.

Twin Laboratories

To enable valid experimentation of the developed technologies, two new laboratories have been established during the ergoCub project: one in Genoa and one in Monte Porzio Catone (RM).

These laboratories are designed as controlled environments to test the developed technologies and verify their effectiveness under conditions similar to those of high-risk workplaces. In particular, the validation scenarios include an exemplification of a scenario where continuous and repetitive load handling is necessary in an industrial context and another exemplification of patient handling in a hospital scenario.

AISM

Collaboration with The Italian Multiple Sclerosis Society

The aims of this study are to examine the capabilities of the quantitative measures derived from iFeel technology and test its usability on a sample of patients with Multiple Sclerosis.

Gait and balance impairment are the most troublesome motor symptoms preventing people from correctly and easily performing daily living activities, with negative effects on working status and social relationships.

Since characteristics of Multiple Sclerosis symptoms may rapidly vary, wearables providing precise, reliable, and valid measures can be the main candidate for balance and mobility assessment.

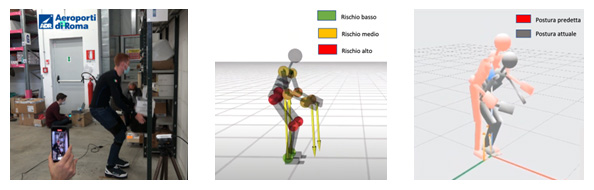

Fiumicino

Experiments in Rome Airport

The wearable technology developed by the ergoCub project has been validated in a real workplace scenario at Aeroporti di Roma. These preliminary experiments allowed the definition and submission of an experimental protocol to the ethics committee to validate the developed technology within real contexts with workers from the manufacturing sector.

The goal is to evaluate both the effectiveness of monitoring and preventing workers' biomechanical risk and the suitability and usability of the technologies by the target users.

CE Certifications

The ergoCub project has made significant strides towards the certification of the developed technologies: the wearable technology, for example, has undergone the necessary pre-compliance tests for CE certification, and the sensorized shoes have undergone the necessary tests to initiate the medical certification process.

However, the Italian Institute of Technology (IIT) is a private non-profit foundation, which prevents the sale of the technology developed in the ergoCub project to national and international organizations interested in it.

For this reason, the ergoCub project is working towards establishing a spinoff named iFeel, which can facilitate technology transfer from research institutes such as IIT and INAIL to workplaces, as the spinoff is entitled to sell and distribute technologies transferred from the ergoCub project.